The Ultimate Guide to

Environmentally Friendly Packaging

Sustainable packaging isn’t just a material swap—it’s a system change. In this guide, you’ll get a crisp definition of environmentally friendly packaging, why it matters in 2026, and how to choose the right solutions for your category. We’ll compare molded fiber (wood, bagasse, bamboo), paper-based formats, and leading bioplastics; unpack performance trade-offs like moisture resistance, grease/oxygen barriers, and end-of-life; and show where eco packaging truly beats traditional plastic on footprint, compliance, and brand perception.

From there, we’ll turn strategy into execution. You’ll see real use cases across FMCG, beauty, pharma/healthcare, e-commerce/3PL, retail private-label, dairy/chilled, and co-packers. We’ll walk through design and branding without greenwashing, the cost & ROI model (including EPR fees), and what PPWR and EPR mean for you. Finally, you’ll get a step-by-step transition roadmap (prototype → pilot → scale), plus the metrics, certifications, and audit trails you need for internal sign-off and retailer/regulator scrutiny.

What Is “Environmentally Friendly Packaging”?

Short definition: Environmentally friendly packaging (often called eco-friendly packaging) is packaging that minimises environmental impact across its life cycle — by using less material, designing for reuse or high-quality recycling, reducing CO₂ and waste, and avoiding harmful substances—while still protecting the product and complying with regulations (e.g., EU PPWR design-for-recycling rules and EPR). See EU PPWR objectives and timelines: https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en)

How it differs from “eco-friendly”, “sustainable”, and “green”

- Eco-friendly / green are umbrella marketing terms. Use them only when you can substantiate the claim with standards, LCA results or certifications. The Ellen MacArthur Foundation frames credible packaging progress around eliminating the unnecessary, shifting to reuse where relevant, and ensuring the rest is reusable, recyclable, or compostable in practice.

- Sustainable packaging focuses on whole-of-life performance (LCAs, end-of-life outcomes, and supply-chain effects). This is widely used in guidance and literature.

(https://en.wikipedia.org/wiki/Sustainable_packaging) - Regulatory terminology in the EU is getting precise under the PPWR: all packaging must be recyclable by 2030, and by 2035 “recyclable in practice and at scale” (collected, sorted, and recycled in existing EU infrastructure), with detailed design-for-recycling criteria and fee modulation under EPR.

Glossary

- Design for Recycling (DfR): Packaging structure, materials, colours, labels, and closures designed to achieve high-quality sorting and recycling in the EU system—soon tied to EPR fee grades.

- EPR (Extended Producer Responsibility): Producer/brand pays and often operates end-of-life management, with fees modulated by recyclability/performance. (https://www.europen-packaging.eu/policy-area/extended-producer-responsibility/)

- Reusable / Recyclable / Compostable (credible use): Use per recognised frameworks; not all compostables are appropriate—best fit is often food-contact organics capture.

Why the definition matters

- 186.5 kg of packaging waste were generated per EU resident in 2022; plastics made up ~19.4% of packaging waste materials.

Source: Eurostat overview. - All EU packaging must be recyclable by 2030, with enforceable design-for-recycling criteria and “recycled at scale” definitions entering EU law (application begins 18 months after PPWR’s entry into force on 11 Feb 2025). EU Commission page + legal analysis.

- Packaging is the largest source of plastic waste: around 38% in Europe, underscoring why packaging redesign delivers outsized impact. OECD/Our World in Data synthesis. (source: https://ourworldindata.org/data-insights/packaging-is-the-source-of-40-of-the-planets-plastic-waste )

In 2025, “environmentally friendly packaging” in the EU means meeting performance needs with the least material and impact, designed for reuse or real-world recycling, and documented to satisfy PPWR/EPR. This locks your brand’s sustainability claims to verifiable outcomes, not vague labels.

Why Packaging Sustainability Matters in 2026

Regulation is now a market reality. The EU’s new Packaging and Packaging Waste Regulation (PPWR) entered into force on 11 Feb 2025, with a general date of application 18 months later. In practice, most provisions start applying from August 2026, with further phase-ins through 2040. That means design-for-recycling, waste-reduction targets, and EPR fee modulation are no longer “nice to have”—they’re budget and roadmap items for 2025–2026.

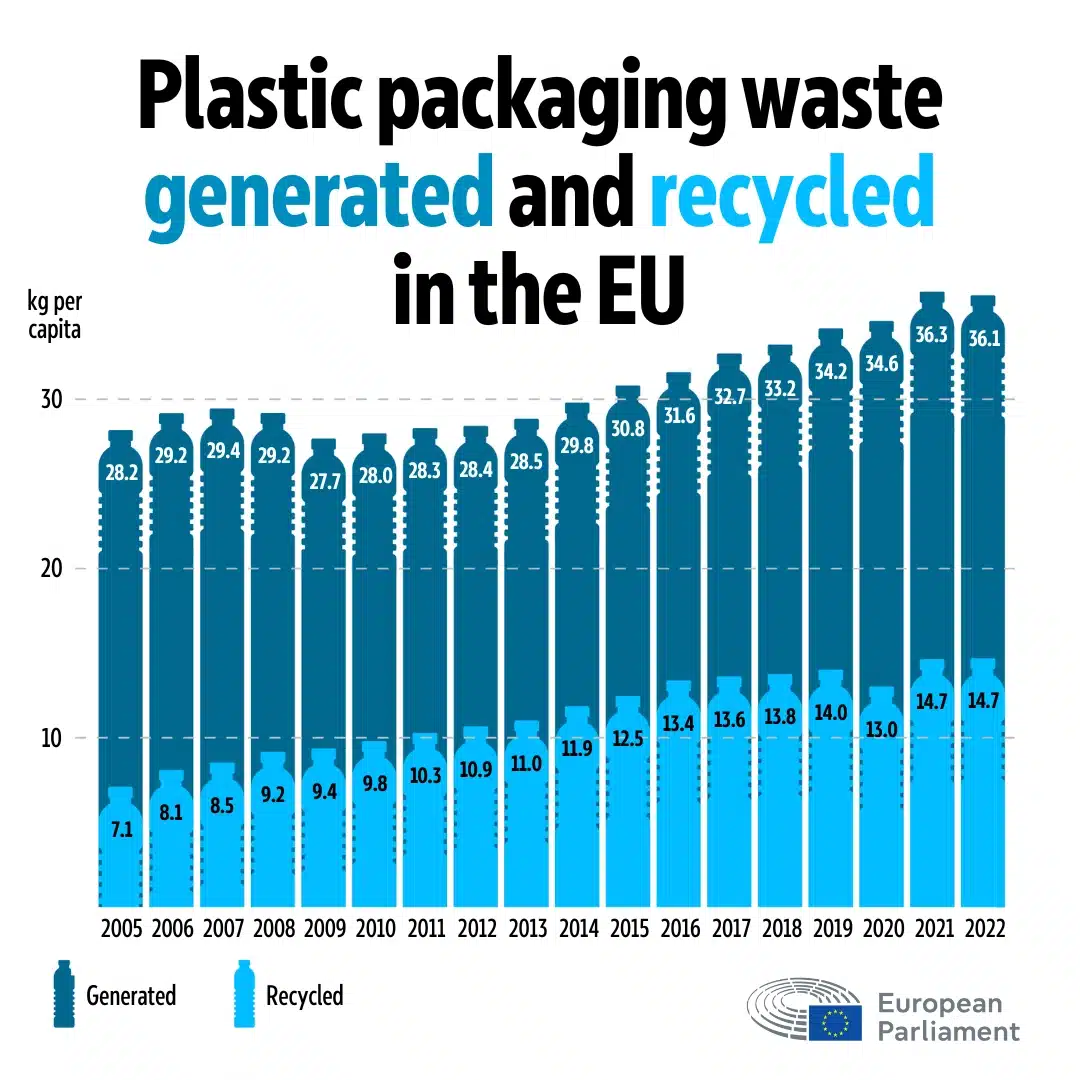

The waste and plastics baseline is too large to ignore. EU residents generated ~190 kg of packaging waste per person in recent years, and plastic packaging waste reached 16.16 million tonnes in 2022, with only 40.7% recycled. This is why the PPWR’s “recyclable by 2030” and “recyclable in practice and at scale” requirements are so central to brand packaging decisions.

Sources: Eurostat & European Parliament stats pages, Reuters PPWR deal recap

EPR fees will hit (or help) your P&L. Under EU rules, EPR fees are modulated—i.e., lower for packaging that’s easier to recycle, higher for formats that aren’t. This creates a direct financial incentive to shift from problematic plastics to fiber-first designs that meet DfR criteria. In 2025, fee levels vary significantly by country (e.g., €48/tonne for aluminium in Belgium vs €1,090/tonne in Sweden), showing why procurement and finance should evaluate total landed cost rather than unit price alone.

Demand-side pressure hasn’t vanished—just shifted. European consumers still care about sustainability, but price sensitivity is higher than in 2020–2023. McKinsey’s 2025 survey notes a larger share of consumers are unwilling to pay more for sustainable packaging compared with pre-inflation years; at the same time, PwC’s global 2024 study found buyers will pay an average 9.7% premium for sustainable products when value is clear. Translation: you’ll win when eco formats protect the product, look premium, and don’t inflate shelf price.

Sources: McKinsey , PwC Voice of the Consumer 2024

Supply-chain governance is tightening. Beyond packaging-specific rules, the Corporate Sustainability Due Diligence Directive (CS3D) and related initiatives push large companies to run transition plans and verify responsible sourcing—affecting packaging materials choices, traceability, and mass-balance accounting for recycled content. Even with evolving thresholds, the direction of travel for 2025–2027 is clear: better data, better proof.

What this means for teams in 2026?

Build business cases that combine compliance milestones, EPR fee outcomes, and consumer-ready design. If your eco alternative reduces damage rates, hits DfR criteria, and keeps costs predictable, it will outperform legacy plastic formats—commercially and regulatorily.

Core Principles: Reduce, Reuse, Recycle & Regenerate

Start with the waste hierarchy. In the EU, prevention (use less) is the top priority, followed by preparing for reuse, recycling, recovery, and landfill last. Treat this as your decision ladder for every SKU refresh: Can we remove it? Can we make it reusable? If single-use remains necessary, can we make it highly recyclable in today’s EU systems?

Anchor on circular-economy outcomes, not labels. The Ellen MacArthur Foundation’s packaging vision is crisp: eliminate the unnecessary, innovate so the rest is reusable, recyclable or compostable, and circulate materials to keep them in the economy and out of nature. Use this to frame trade-offs in stakeholder reviews.

Design to standards you can audit. The ISO 18601 family sets packaging-and-environment requirements across the life cycle (material efficiency, reuse, recycling, energy recovery, organic recycling). Mapping your specs to these clauses—and to EU PPWR DfR criteria—makes your claims defensible in 2025 vendor and retailer audits.

A practical checklist you can copy into briefs

1) Reduce (Material & Component Efficiency)

- Eliminate non-functional components (e.g., window films, foam inlays) or lightweight them without compromising protection. Tie reductions to ISO 18602/18601 principles for documentation.

- Consolidate SKUs and dielines so one recyclable mono-material works across variants (simplifies EPR reporting and boosts sortability). Align with EU waste-prevention priority.

2) Reuse (Where It Truly Fits the Journey)

- Prioritise closed-loop or controlled logistics flows (e.g., B2B component trays, refill totes) where reverse logistics are reliable. Align your decision with the hierarchy and circular design logic.

- Document reusability criteria (turns, cleaning, damage rate) so finance can compare reuse vs. single-use total landed cost and EPR exposure.

3) Recycle (Design-for-Recycling as a Default)

- For rigid & flexible plastics, apply RecyClass DfR guidance and (for flexibles) CEFLEX D4ACE to avoid common incompatibilities (e.g., dark carbon-black, incompatible adhesives, PET/PE laminations in PE streams, metallisation in PP where not permitted). This is the clearest route to “recyclable in practice and at scale.

- For paper/fibre, use credible chain-of-custody (e.g., FSC®) and verify that barrier choices (dispersion coatings vs. plastic films) keep the pack in a high-yield paper stream. Never over-state FSC; follow official trademark rules.

4) Regenerate (Composting & Biobased—use selectively)

- Reserve EN 13432 industrial compostable formats for use cases that aid organics capture (e.g., food-soiled items, caddy liners), not as a blanket substitute for recyclable fibre. Cite the standard in specs and QA tests (disintegration, biodegradation, eco-toxicity).

- If you use biobased plastics (PLA, PHA, bio-PET), separate “bio-based” (origin) from “biodegradable/compostable” (end-of-life). Then check local collection/recycling reality against EMF’s “in practice and at scale” principle.

How to turn principles into sign-off criteria

- Evidence framework: Map each design choice to (a) waste-hierarchy step, (b) DfR guideline (RecyClass/CEFLEX or paper mill guidance), and (c) standard (ISO 18601 family, EN 13432, FSC COC). This creates a paper trail for PPWR/EPR audits.

- Gate checks: At design freeze, require (1) recycling stream & grade target, (2) label/ink/adhesive compatibility, (3) barrier impact on recyclability, (4) evidence of sourcing certification where claimed.

- Language discipline: Ban vague claims (“eco”, “green”) unless tied to verifiable outcomes (e.g., DfR grade, EN 13432 certificate, % certified fibre). Aligns with EU direction and prevents greenwashing.

Takeaway: Use Reduce → Reuse → Recycle → Regenerate as a strict funnel. If a design decision can’t be justified against the hierarchy, DfR guidance, and recognised standards, it won’t pass 2026 compliance scrutiny—or consumer sniff tests.

Common Eco-Friendly Packaging Materials

(Overview)

What you’re choosing between (quick map): most “environmentally friendly packaging” portfolios centre on molded fiber (wood pulp, bagasse, bamboo), paper-based formats (cartonboard, corrugated, specialty papers), and bioplastics (PLA, PHA, bio-PET). Each has different barrier options, end-of-life routes, and regulatory fit in the EU.

Expert view—fit for 2025 PPWR/EPR:

- Fiber first is strong where paper recycling systems are mature: Europe recycled 79.3% of all paper and board consumed in 2023 (a record), with paper-based packaging typically even higher. Source: CEPI monitoring & EPRC updates

- Molded fiber can now achieve better moisture/grease resistance via chemistry (e.g., dispersion coatings), while staying recyclable within paper streams when properly designed.

- Bioplastics are not one thing: bio-based ≠ biodegradable. Some (e.g., PLA) can be mechanically recycled or industrially composted when systems exist, but collection reality and DfR rules determine viability SKU-by-SKU.

Sources: European Bioplastics EoL paper; EN 13432 performance note

Molded Fiber (wood, bagasse, bamboo):

where it shines

Use cases: protective trays/inlays for electronics and beauty sets, on-the-go foodservice, e-commerce void-fill alternatives.

Pros: renewable inputs (including non-wood like bagasse/bamboo), formable geometry, curbside paper-stream compatibility when coatings/inks are chosen well. Scholarly reviews highlight the momentum of non-wood pulps (bagasse, wheat, bamboo) for cost and renewability.

Watch-outs: water/grease barrier choices can make or break recyclability; choose repulpable dispersion coatings and DfR-friendly inks/adhesives. Industry guidance notes chemistry enables water-repellency without derailing recyclability when specified correctly.

Market signal: analyses point to improved gas/moisture control as a driver for molded fiber adoption in food applications, accelerating the shift from plastics. Example: market review

Paper-Based Formats (cartonboard, corrugated, specialty papers):

the EU workhorse

Why it’s compelling: Europe’s paper systems handle high volumes with >79% recycling (2023), giving brands a clear route to “recyclable in practice and at scale”.

Pros: excellent printability and premium finishes, wide converter base, strong EPR positioning thanks to established collection/sorting.

Limits & caveats: barrier papers (e.g., with PE films, foils, or heavy polymer layers) can fall out of high-yield paper streams; NGOs and technical reports flag recyclability constraints when coatings/laminates are not mill-friendly. See European Environmental Bureau paper.

Bioplastics (PLA, PHA, bio-PET): use with system thinking

Where they fit: niche food-contact (e.g., produce trays, liners) or formats where composting supports organics capture; bio-PET fits existing PET recycling streams when purity and infrastructure allow.

Pros: PLA can be mechanically recycled or industrially composted (EN 13432) when separate streams exist; PHA offers novel biodegradation pathways under specific conditions.

Cautions: do not assume home compostability or drop-in recyclability. Your DfR baseline for plastics in the EU remains RecyClass (and APR for US exports); follow their component-level rules to avoid downgrading entire streams.

Reality check: Waste-management studies continue to stress industrial (not home) composting readiness for many biodegradable plastics and the need for controlled conditions to realise environmental benefits.

Decision tip: Start with fiber for mainstream EU recyclability and brand storytelling; use bioplastics selectively where they enable organics capture or fit existing PET loops—and always validate against RecyClass/EN 13432 and local collection reality.

Molded Fiber:

Wood Pulp, Bagasse, Bamboo Pulp

Where molded fiber fits in 2026: Fiber-thermoformed trays, inlays, and clamshells are now credible replacements for EPS, PET and PVC in many applications—especially where EU recyclability in paper streams and premium feel matter (beauty/electronics sets, e-commerce protective fitments, some foodservice). Recent reviews and theses show steady gains in mechanical strength and barrier add-ons, particularly for non-wood pulps like bagasse and bamboo.

Material choices & trade-offs (wood vs. bagasse vs. bamboo):

- Wood pulp offers consistent quality and established supply; fiber networks are well understood for forming precision trays. Comprehensive reviews outline stable forming, but moisture/grease resistance usually requires coatings or sizing.

- Bagasse (sugarcane residue) brings good stiffness-to-weight and availability in EU-import supply chains. Lab work shows shellac and other bio-coatings can significantly improve water and grease resistance on bagasse paperboard, supporting food packaging scenarios—provided the coating remains repulpable or the pack is routed to organics where appropriate.

- Bamboo pulp typically has long fibers and favorable strength; studies report strong reinforcement options and growing use as a non-wood input in pulp and paper. For molded formats, fiber blending can tune tensile and porosity, which is useful for shock absorption in electronics/beauty trays.

Barrier performance without derailing recyclability: The industry is moving from PFAS toward PFAS-free dispersion coatings (e.g., acrylics, starch, MFC/CNF-based) to achieve water/grease resistance while keeping fiber in high-yield paper streams. Multiple technical sources discuss the performance of dispersion or cellulose-nanomaterial barriers that lower WVTR/OTR and grease penetration, with recyclability validated via repulping tests. (See OECD’s PFAS-alternatives report; MFC/CNF barrier research; recyclability testing protocols.)

Practical design guidance (get DfR right from day one)

- Target paper-mill compatibility: Follow 4evergreen “Circularity by Design” guidance and CEPI recyclability principles—minimise non-fiber elements; make them easily separable; and use mineral-oil-free inks where possible. This is your shortest path to “recyclable in practice and at scale” claims in the EU.

- Choose repulpable coatings: Where you need moisture/grease barriers, prefer repulpable dispersion systems; avoid heavy PE laminates or complex films that can push packs out of high-yield paper streams. AF&PA’s mill survey–based design guidance echoes these cautions and is useful even for EU designers.

- Engineer the fiber network: For high-precision trays (electronics, cosmetics), tune fiber blend and refining; studies on bagasse/bamboo blends show tensile/porosity can be adjusted for cushioning and form definition. Run forming trials to lock in wall thickness and de-nesting angles early.

- Declare what’s inside (PFAS-free and adhesives): Regulators and retailers increasingly scrutinise PFAS in food-contact papers; document your barrier chemistry and provide supplier letters of assurance or third-party testing to back “PFAS-free” claims.

- Validate with lab repulping: When you introduce a new coating, run a standardised repulpability test and include results in your technical file; research shows robust protocols (e.g., for acrylic dispersions vs. LDPE laminates) can de-risk EPR and mill acceptance discussions.

Where molded fiber wins (and where it doesn’t)

- Wins: premium unboxing and sustainability cues; curbside paper stream compatibility when designed per DfR; thermoformed precision for protective fitments; rapidly renewable inputs (bagasse/bamboo) that support brand storytelling.

- Watch-outs: direct contact with wet/greasy foods still needs carefully specified barrier systems; over-lamination or dark, non-deinkable prints can harm recyclability; extreme moisture exposure in the supply chain (e.g., cold chain condensation) requires line trials and possibly hybrid solutions.

Decision tip: If your brief prioritises EU recyclability, brand feel, and EPR friendliness, start with molded fiber and validate barrier performance with PFAS-free dispersion coatings that pass repulpability tests. Keep the structure mono-material; make all labels and inserts paper-based and easily separable.

Paper-Based Formats:

Cartonboard, Corrugated, Specialty Papers

Why paper is the EU workhorse. Europe’s fibre systems are mature and high-performing: in 2023, 79.3% of all paper and board consumed in Europe was recycled, according to the European Paper Recycling Council’s Monitoring Report. Paper packaging specifically posts even higher rates in most markets, with 2025 updates noting that the majority of European countries exceed 70% overall and paper packaging reaches ~83%. These numbers are why paper is often the fastest route to “recyclable in practice and at scale” under PPWR/EPR.

Design-for-recycling (DfR) essentials. Use the 4evergreen “Circularity by Design” guideline (v3, Oct 2024) to specify mono-material paper structures, mill-friendly coatings/adhesives, easily removable components, and de-inkable print. The guidance spans standard mills (Part I), flotation-deinking mills (Part II) and specialised processes (Part III), and sets clear tests for compatibility—useful for spec sheets and supplier briefs. Where you need recyclability proof for buyers or retailers, a practical route is the UK’s Papercycle assessment and certification (aligned with CPI and referencing CEPI tests) to diagnose whether a given paper pack is recyclable and in which mill types.

The coating/laminate caveat (don’t ignore it). Food and beverage paper formats often add barrier layers (PE films, foils, heavy polymer coatings). Multiple studies and NGO reviews warn that these composites can push packs out of high-yield paper streams if not carefully designed; some mills struggle when non-paper content rises above low single-digit thresholds. In other words: pick repulpable dispersion coatings (or separable solutions) and validate with recognised tests—don’t assume “paper = recyclable” by default.

Cartonboard & corrugated: how to brief converters.

- Cartonboard (FBB/SBS/CUK): specify de-inkable inks, water-removable adhesives, fibre-friendly barriers (e.g., aqueous dispersions) and avoid dark, carbon-black areas that hamper optical sorting in mixed waste streams. 4evergreen’s tables flag common do’s/don’ts by component.

- Corrugated: leverage high recycled content and proven recovery rates, but be strict on spot varnishes/laminates and plastic windows—make them easily separable or drop them. Align with 4evergreen Part I recommendations for standard mills.

- Specialty papers (barrier/functional): if you need grease/moisture protection, prefer aqueous dispersion systems rather than heavy extrusions; recent design reviews show dispersions can hit similar barrier targets with lower non-cellulosic content—keeping you in better shape for mill acceptance and EPR fees.

Procurement/QA shortcut. Add two artifacts to every paper-pack spec: (1) a 4evergreen DfR mapping page that lists substrate, ink, adhesive, label, closures, and barrier against the guideline’s acceptance criteria; and (2) a Papercycle (or equivalent) recyclability determination for the final construction—even better if it states the compatible mill classes. This pair dramatically reduces back-and-forth with retailers and compliance teams.

Takeaway: Paper formats can deliver premium printability, strong brand cues, and top-tier EU recyclability—if you keep structures mono-material, choose repulpable barriers, and document recyclability with 4evergreen + Papercycle evidence.

Bioplastics Explained:

PLA, PHA, Bio-PET — Pros & Trade-offs

What bioplastics are (and aren’t)? “Bioplastic” is an umbrella for plastics that are bio-based, biodegradable/compostable, or both. Bio-PET is chemically identical to PET but made partly from bio feedstocks, so it recycles in the PET stream when designed per DfR; PLA and PHA are different polymers that may be mechanically recycled in dedicated loops or industrially composted where facilities and collection exist. Your default EU baseline for plastics remains RecyClass Design-for-Recycling: check caps, inks, labels, adhesives, colourants and multilayer structures against its stream-specific rules before you claim recyclability.

PLA (polylactic acid): PLA is widely used in thermoformed trays, cups and wrap films. It can be mechanically recycled in closed loops or sent to industrial composting when certified to EN 13432—but don’t assume home compostability or curbside acceptance. EN 13432 requires proof of biodegradation, disintegration (≤10% >2 mm after 12 weeks) and non-toxicity under controlled conditions, and many municipalities do not accept PLA in organics unless local policy says so. In short: strong option for controlled systems (events, campuses, foodservice with organics capture), weaker fit for mixed municipal waste.

PHA (polyhydroxyalkanoates): PHAs are a family of bio-polyesters with promising biodegradation profiles under certain conditions (industrial composting; some aquatic/soil contexts), but kinetics vary by PHA type, temperature, nutrient load and humidity. Recent peer-reviewed work (2025) shows PHAs can reach ≥90% conversion under specified lab/field conditions, while other studies highlight slower or minimal breakdown in cooler, drier environments—so real-world outcomes depend on local conditions and product geometry. Treat PHA as a targeted solution where composting infrastructure exists or where leakage risk is material to the LCA, and back claims with current data.

Bio-PET (and PET trays): Bio-PET behaves like fossil PET in recycling—the chemistry, not the feedstock, determines compatibility. RecyClass notes PET bottles are well-established, but PET trays still face collection/sorting challenges in many EU regions; trays often contaminate bottle bales unless separately sorted. If you specify bio-PET, design to the bottle DfR where applicable, or confirm tray-specific sorting/recycling exists in your markets before making claims.

How PPWR changes the bar (2030 → 2035+): Under PPWR, by 2030 all packaging placed on the EU market must be designed for recycling, and by 2035 it must be “recyclable in practice and at scale,” with stream-specific criteria and EPR fee modulation to match. That means bioplastic choices must be justified SKU-by-SKU against the actual EU recycling or composting pathway available, not theoretical ones. Use PPWR explainers and national operator guidance to document which stream you’re targeting and why it’s available today in your top markets.

Decision tip:

- PLA → great in closed systems with industrial composting or dedicated take-back; avoid vague “compostable” claims in markets without facilities.

- PHA → use where composting or leakage mitigation is critical—and cite current degradation data for the specific grade and conditions.

- Bio-PET → stick to PET bottle loops or confirm PET tray infrastructure; follow RecyClass DfR to protect flake quality.

Eco Packaging vs Traditional Plastic

— Performance & Footprint

There’s no one-size-fits-all winner. Peer-reviewed LCA syntheses comparing plastics with alternative materials conclude that outcomes are context-dependent (format, barrier needs, logistics, end-of-life). Plastics can be efficient on mass and energy for high-barrier food protection; fibres can outperform where paper recycling is strong and barriers are modest. Treat the choice as a system decision, not a material label.

|

Criterion |

Fiber-based (molded fiber / paper) | Conventional plastics (PE, PP, PET) | What this means for teams |

| Recyclability “in practice & at scale” |

Europe recycled 79.3% of all paper & board in 2023; paper packaging typically higher. Barrier/laminate choices still matter. |

Plastic packaging recycling in the EU was 40.7% in 2022; stream rules are strict by polymer/format. |

Fibre gives an easier path to PPWR “recyclable by 2030” if barriers are repulpable; plastics must follow RecyClass stream rules. |

| CO₂e footprint (LCA) | Often favourable for low-barrier applications and where paper is widely recycled; coatings add impacts. | Frequently lower per unit performance when high barrier/long shelf-life is essential (less product spoilage). | Model product+pack together; product waste often dominates footprint, making barrier performance critical. |

| Barrier performance (OTR/MVTR, grease) |

Strong progress with PFAS-free dispersion coatings; still below top multilayer plastics for extreme OTR/MVTR. |

Broad spectrum—from mono-PE films to advanced EVOH/multilayers that hit very low OTR/MVTR. | Pick the minimum barrier that protects the product and preserves recyclability. Validate in line trials. |

| EPR exposure (fees) |

Typically lower-modulated fees where recyclability is high and non-paper content is low. |

Fees vary widely and rise with poor recyclability; e.g., 2025 aluminium fees range from €48/t (BE) to €1,090/t (SE)—illustrating variance across materials too. | Compare total landed cost incl. EPR, not just unit price. |

| Sorting/recycling infrastructure nuances |

Mature curbside and mill capacity, but heavy laminates can knock formats out of high-yield streams. |

PET bottles have robust loops; PET trays remain limited in many EU markets unless separately collected/sorted. | Confirm the actual stream (by country) before making claims |

| Damage & logistics |

Custom molded-fiber fitments reduce void; corrugated right-sizing cuts weight/air. |

Film cushioning and engineered plastics protect fragile goods well; oversized packs increase cube and damage risk. | Right-sizing + verified protection lowers damage and returns (case evidence across retail/e-com). |

|

Brand/UX

|

Tactile, “natural” feel; strong premium unboxing. | Transparent, glossy, high clarity for food visibility. | Choose the brand cue that also matches the end-of-life story. |

Context matters. If your SKU doesn’t need extreme barriers, PFAS-free, repulpable fiber solutions usually offer the clearest EU recycling path and EPR upside; for oxygen-sensitive or sterile use, design plastics to the named stream and prove it.

Reality check: Europe recycled 79.3% of paper & board in 2023 (CEPI/EPRC), while plastic packaging reached 40.7% recycling in 2022 (EP). PET trays still lag bottles in collection/sorting in many EU markets—claims must be market-specific.

Barrier Performance & Moisture Resistance

(Coatings, Laminates)

What “barrier” really means: In practice you’re balancing water-vapor (WVTR/MVTR), oxygen (OTR) and grease/oil resistance against recyclability and food-contact safety. The 2024–2025 guidance is clear: for fibre-based packs, start with PFAS-free solutions (e.g., aqueous dispersion systems, polysaccharide/protein/lipid hybrids, and cellulose-nanofibril/CNF layers) and validate repulpability; for plastics, follow RecyClass stream-specific thresholds for barrier layers like EVOH and for laminating adhesives.

How much protection can paper-based barriers deliver? Recent peer-reviewed work shows stacked/“double” coatings and CNF hybrids can cut WVTR by ~40–70% versus single layers, and CNF/nanoclay/PVOH chemistries further lower permeation on molded pulp trays—evidence that PFAS-free stacks can reach demanding moisture/grease specs when engineered well. The trade-off: barrier mass and binder choice influence repulpability and mill yield, so you must confirm compatibility using fibre-sector DfR protocols (e.g., 4evergreen and CPI/Papercycle).

Grease resistance without PFAS. A 2025 industry/scientific review documents the rapid pivot to PFAS-free barriers across paper and molded fibre, with viable alternatives (e.g., starch or acrylic dispersions, biopolymer blends) now deployed at scale for many food-contact SKUs. NGO and technical reports add an important caution: food packaging that relies on heavy plastic laminates to achieve grease/water resistance can drop out of high-yield paper streams—designers should prefer repulpable dispersions or separable structures and prove recyclability with mill-aligned testing.

Design choices that protect performance and recyclability

- If you need a barrier on fibre, go “dispersion-first.” Use aqueous dispersion coatings (e.g., acrylic/PVOH/MFC-based) before considering film laminates. Then document recyclability with 4evergreen Circularity by Design (v3, 2024) and, where relevant, a Papercycle determination stating which mill types accept the structure.

- Engineer the stack, then lab-test. Layering CNF with pigments or nanoclay can materially lower WVTR/OTR on trays and boards; validate with standard cup tests and grease kits and a repulpability assessment to catch fibre-loss issues early.

- Mind the plastic barrier limits. For PE films, EVOH ≤ ~5 wt% (with suitable tie layers) shows minor impact on recyclate quality; above that, process penalties appear. RecyClass’ Design Book and 2024 Technical Review (laminating adhesives + EVOH) explain the thresholds and interactions you should write into specs.

- Avoid “hidden” recyclability killers. Excessive laminating adhesive, dark carbon-black areas, and non-separable foils can tip both paper and plastics out of preferred streams; run a DfR check (4evergreen/CPI for fibre, RecyClass for plastics) before artwork lock.

- Use third-party guidance to speed sign-off. Mill-surveyed design rules from AF&PA (useful reference even in EU contexts) help predict how coatings/additives behave in repulpers; pair this with your EU evidence for a robust audit trail.

When to choose laminates (and how to do it safely)

- Choose laminates only when performance demands it (e.g., aggressive grease, condensation, or oxygen-sensitive SKUs where fibre-only stacks can’t hold spec). If you must laminate, design for easy separation (e.g., peelable liners) or keep non-fibre content as low as possible to remain within fibre-mill tolerance windows. Document the separation method in QC SOPs.

- For plastic structures, laminate choices (adhesives + EVOH) must still satisfy the target recycling stream’s limits; otherwise you risk downgrading bales and incurring higher EPR fees. The RecyClass Design for Recycling portal and annual updates are your canonical references.

Bottom line: Aim for PFAS-free dispersion or CNF-based barriers on fibre whenever possible and write recyclability into the spec from day one. For plastics, design to the named recycling stream and respect EVOH/adhesive thresholds. In both cases, back claims with DfR + repulpability evidence so your barrier doesn’t solve moisture problems by creating recycling ones.

Design, Customization & Branding

— Without Greenwashing

Make it beautiful—and compliant. The 2025 landscape rewards packs that look premium and can prove their claims. In the EU, PPWR tightens design-for-recycling and labelling, while green-marketing rules are converging: the Empowering Consumers Directive (EU) 2024/825 bans vague, generic claims and unverified eco-labels; the separate Green Claims Directive proposal has been paused/uncertain since June 2025—but the Commission still expects substantiation for environmental claims. In short: design boldly, claim cautiously, document everything.

Source: https://www.reuters.com/legal/legalindustry/eu-tackles-greenwashing-empowering-consumers-directive-proposals-future-2024-05-16/

Brandable elements that help recyclability

(and your audit trail)

- Ink & coating choices for paper: use mineral-oil-free systems and follow EuPIA guidelines for food-contact inks and photoinitiators; several EU markets are tightening restrictions on MOAH/MOSH in prints from 1 Jan 2025.

- Keep fibre mono-material: favour aqueous dispersion topcoats for matt/gloss/grease-resistance over heavy plastic laminates; validate with Papercycle or equivalent plus a 4evergreen mapping sheet.

- Smart colour work on plastics: avoid carbon-black masterbatches that block NIR sorting; use certified NIR-detectable blacks or lighter tones, and check stream-specific RecyClass DfR notes (ongoing 2025 testing on black inner layers).

- Right-size & structural branding: premium unboxing doesn’t require foam. Sculpted molded-fibre fitments and precision corrugate cues reduce void space and EPR exposure while elevating brand feel. Tie each change to a DfR guideline in your spec.

How to claim sustainability without greenwashing

- Use ISO 14021 language for self-declared claims. If you say “recyclable,” “recycled content,” or “compostable,” apply ISO 14021 definitions and keep the verification file (method, sampling, results). This is the safest cross-border baseline.

- Prove the stream exists—today. Under PPWR, “recyclable in practice and at scale” means the pack is actually collected, sorted and recycled in your markets. Link each claim to the target stream (e.g., PET bottle vs. PET tray) and cite operator guidance or certifications.

- Label certifications correctly. If you use FSC®, follow the Trademark Standard (FSC-STD-50-001 V2-1) and the official artwork rules—only chain-of-custody certificate holders can label on-pack. Keep this in your brand guidelines.

- Avoid generic claims banned by consumer law. The EU’s consumer-protection update outlaws unverified generic claims (“eco-friendly”, “green”) and unaccredited labels. UK casework under the CMA Green Claims Code shows regulators expect specific, accurate statements (e.g., “mono-PE pouch, designed for EU PE film recycling where available”).

Customisation patterns that convert

(and pass compliance)

- Texture & finishes (paper): uncoated, tactile boards signal “natural” while staying de-inkable; if you need gloss, choose water-based dispersions and document repulpability. Pair with low-coverage dark areas to help de-inking.

- Emboss/deboss over plastic windows: structural branding beats materials that harm sortability. If a window is essential, make it easily separable (tear-strips, mono-material labels) and disclose it in the DfR sheet.s

- Colour strategy (plastics): use light, NIR-friendly colours; if black is a must, specify IR-reflective pigments verified by recyclers. Reference APR/RecyClass notes in the artwork brief.

- QR for proof: link on-pack QR to a public page with your spec highlights (DfR target stream, coatings, certifications, LCAs). This doubles as consumer education and retailer/regulator audit support. (Aligns with PPWR labelling direction: material ID pictograms by 2028.)

Copy blocks you can reuse (edit to your SKU)

- Recyclability (fibre): “Mono-material paperboard with aqueous dispersion barrier. Assessed under 4evergreen DfR; recyclable in paper mills suitable for dispersion-coated boards (market-dependent). Evidence available.”

- Recyclability (plastic): “Mono-PE film with EVOH <5% and compatible adhesives; designed to RecyClass DfR for the PE film stream. Sorting/recycling availability varies by country.”

- Sourcing: “Board sourced under FSC® Chain of Custody; on-pack trademark used per FSC-STD-50-001.”

- No greenwashing: “We avoid generic claims (e.g., ‘eco’, ‘green’). All statements are supported by standards (ISO 14021), certifications, or operator guidance.”

Takeaway: Let customisation drive clarity, not complexity. Choose finishes and colours that aid sorting, pick coatings that keep fibre in the mill, and write claims in standards-based language with evidence one click away. That’s premium branding that stands up in 2026.

Benefits

— CO₂ Reduction, Waste Management, Branding & Logistics

Why this matters to P&L and sustainability KPIs: the right eco-pack does three things at once — cuts emissions and waste, lowers EPR exposure/operational costs, and lifts brand preference.

Below is a pragmatic view you can take to the board.

CO₂ reduction (without risking product loss)

- Right-size to cut freight emissions. Oversized packs ship air, raising transport CO₂. Sector analyses report on average 55% empty space in e-commerce boxes—an enormous optimization headroom for cube reduction, pallet density and route efficiency.

- Design for the product’s true barrier needs. LCA research shows the product footprint often dominates, so choose the minimum barrier that prevents spoilage/damage (especially for food/fragile goods). A classic LCA synthesis demonstrates that better protection—even with slightly higher packaging impacts — can lower overall CO₂e.

Waste management and EPR exposure

- Leverage high-yield fibre loops. Europe recycled 79.3% of paper & board in 2023, supporting fibre-first designs that stay in mill-friendly streams when barriers are repulpable.

Source: EPRC Monitoring Report 2023 (CEPI). - Know the plastics baseline you’re competing with. Plastic packaging recycling in the EU was 40.7% in 2022 (16.16 Mt generated; 6.58 Mt recycled), so DfR compliance and stream choice (e.g., PET bottle vs. tray) materially affect fees and claims.

EPR fee modulation rewards recyclability. 2025 guidance from EUROPEN stresses that eco-modulated fees increasingly incentivise designs that are collected, sorted, and recycled at scale—so mono-material fibre or RecyClass-compliant plastics can reduce fee burden over time.

(Source: https://www.europen-packaging.eu/wp-content/uploads/2025/02/EUROPEN-EPR-Recommendations-January-2025.pdf)

Branding & conversion (without greenwashing)

- Consumers reward credible sustainability. PwC’s 2024 Voice of the Consumer finds buyers are willing to pay an average 9.7% premium for sustainably produced or sourced goods—when the value is clear. Packaging that communicates end-of-life reality (not vague claims) is a direct lever here.

- Unboxing as a trust signal. Clean, mono-material designs with recyclable finishes (e.g., dispersion-coated boards) lower perceived waste while reinforcing premium cues—without blocking recycling. Tie every claim to standards (ISO 14021, FSC® COC, RecyClass/4evergreen) to stay compliant.

Operations: damage rate, returns, logistics cost

- Lower damage = lower footprint + fewer returns. Protective right-sizing (corrugated engineering, molded-fibre fitments) can cut breakage, avoid reverse logistics, and spare the product’s embodied carbon—one of the fastest “silent” decarbonisation moves.

- Fewer SKUs, simpler compliance. Converging to mono-material families (e.g., one recyclable paper structure with format variations) reduces artwork/ink variability, EPR reporting complexity, and supplier risk.

Cost & ROI

— Total Landed Cost, EPR Fees & Payback Scenarios

Why this section matters: switching formats only “wins” if it pays back—in cash and compliance. In 2025, ROI must roll up unit cost + EPR fees + logistics/damage + compliance risk (PPWR/EPR), not just substrate price.

The Total Landed Cost (TLC) model you can copy

Use this worksheet (one line per SKU):

- Unit Pack Cost (materials + conversion)

- EPR Fees (€/tonne × pack mass × country mix) — modulated by recyclability

- Logistics (cube/weight) & Freight — pallet density, truckload utilisation

- Damage/Returns — baseline damage rate × cost-to-serve (reverse logistics, write-offs)

- Compliance Ops — lab tests, certifications, audits (capex/opex amortised)

- Retailer/Channel Requirements — labelling, recyclability evidence, penalties

- Net Cost / Pack = 1 + 2 + 3 + 4 + 5 ± 6

Build scenarios for Status Quo (plastic) vs Eco Alternative (fibre or DfR plastic) and compare per-pack and annual totals.

A simple ROI example

(illustrative math you can swap with your numbers)

Assume current mono-PP tray vs proposed dispersion-coated paperboard tray for a chilled SKU, sold in DE/FR/NL:

- Unit pack cost: PP €0.072 → Paper €0.080 (+€0.008)

- Mass: PP 10 g; Paper 12 g

- EPR fee (illustrative average across markets):

- PP plastic: €600/t (varies by polymer/country)

- Paper: €120/t

- Fees per 1,000 packs → PP: 10 kg × €600/t = €6.00 ; Paper: 12 kg × €120/t = €1.44 → save €4.56 / 1,000

- Freight/cube: Paper tray nests tighter (−6% cube) → saves €0.001 / pack

- Damage/returns: Molded-fibre fitment reduces breakage by 0.3 pp (e.g., from 2.0% → 1.7%), each damage costs €6 all-in. At 100k packs: 300 fewer returns × €6 = €1,800 saved → €0.018 / pack

- Compliance ops: One-off recyclability + migration tests amortised to €0.001 / pack

Net delta / pack:

+€0.008 (unit) − €0.00456 (EPR) − €0.001 (freight) − €0.018 (damage) + €0.001 (compliance)

= −€0.01456 / pack (≈ 1.5 euro-cent saving)

Annualised at 5 million packs: €72,800 savings — with a structure that is easier to defend under PPWR/EPR.

Industry Use Cases & Success Stories

FMCG & Consumer Electronics

- Philips grooming & oral care: moved from large PET blisters to small PET + custom molded-fibre fitments, cutting plastic by ~75% and saving “hundreds of thousands of dollars,” while improving unboxing.

- Right-sized e-commerce packs: DS Smith found ~55% empty space in typical boxes; right-sizing + fibre fitments reduce void fill, freight, and damage.

Beauty & Cosmetics

- Paper-based tubes at scale: L’Oréal × Albéa launched the first paper-based cosmetic tubes (carton-based body replacing most plastic), with LCA to verify benefits; a strong direction-of-travel signal for premium personal care. (https://www.loreal-finance.com/system/files/migrate-files/PR_LOreal-and-Albea_EN_0.pdf)

- Luxury fragrance, plastic-free fitments: multiple luxury brands (incl. Chanel ranges) have deployed molded-pulp inserts to replace plastic vac-forms while keeping the premium feel. (Round-up and trade coverage.)

Pharma & Healthcare

- Paper-based blisters (regulated use): renewable paper-based blister concept for tablets (FSC-certified fibre + barrier coatings) designed for pharma requirements; a pathway away from PVC/Alu where specs allow.

- Recyclable mono-material plastic blisters: Mono-PP and mono-PET blister initiatives (e.g., Push Tab® blister lidding) aim to fit named recycling streams while meeting GMP/line-speed constraints—useful where paper blisters aren’t yet viable.

E-commerce Fulfilment & 3PL

- Paper mailers replacing plastic bubble mailers: Amazon launched recyclable paper protective mailers, removing plastic bubbles while staying curbside-recyclable—useful for apparel, small durables.

- Operational lens: pair right-sized cartons with molded-fibre protective trays to lower returns; your KPIs: cube (-%), damage rate (pp), and cost-to-serve.

Retail Private-Label

- Private-label momentum: PLMA’s 2024 EU report shows retailers prioritising sustainable own-brand packaging in 3–5-year roadmaps—use this to justify packaging upgrades in line reviews.

Dairy & Chilled Food

- Aseptic cartons with paper-based barrier: Tetra Pak × Lactogal introduced an aseptic carton using a paper-based barrier, achieving ~90% renewable content and reporting ~33% CO₂ reduction vs. traditional aseptic structures (vendor LCA). Consider for ambient dairy/juice.

EU Compliance: PPWR, EPR & Claims

(2025–2035)

PPWR is in force (11 Feb 2025); general application ~Aug 2026 with phase-ins to 2035/2040.

By 2030: designed for recycling; by 2035: recyclable in practice & at scale (collected–sorted–recycled).

EU-wide material/sorting labels target by 2028 → prepare artwork/PLM now.

EPR eco-modulation: recyclable designs pay less; fees vary by country—budget per market.

Evidence Pack (attach to every spec)

- Target stream named (paper mill class / plastics stream).

- DfR mapping — Fibre: 4evergreen v3 + Papercycle/CPI result; Plastics: RecyClass thresholds (incl. EVOH/adhesives).

- Label files ready for PPWR pictograms; disposal text localised.

- Claim file ISO 14021 wording; FSC® COC/EN 13432 (if used); supplier LOAs; EPR dossier (country mix, PRO IDs, fee logic).

With compliance framed, let’s move to execution — how to prototype, pilot and scale without rework.

How to Transition:

Prototype → Pilot → Scale

Goal: move from a plastic-heavy baseline to environmentally friendly packaging that meets PPWR/EPR, protects the product, and has proof baked in. Below is a practical, cross-functional playbook you can run in 90–180 days per SKU family.

Phase 1 — Discovery & Target Setting (Week 0–3)

- Scope: pick 1–3 high-volume SKUs per category (FMCG, beauty, pharma, e-com).

- Baseline: capture today’s damage rate, OTR/MVTR needs, mass/cube, EPR fees by country, and end-of-life status.

- Regulatory guardrails: confirm PPWR milestones and what “designed for recycling” vs “recycled at scale” means for your target streams in 2026–2035.

- DfR rails: choose your rulebook now:

- Fibre → 4evergreen Circularity by Design v3 + CPI/Papercycle for recyclability determination.

- Plastics → RecyClass Design for Recycling (use the 2025 Design Book for thresholds like EVOH/adhesives).

- Data & labelling: align artwork to upcoming harmonised EU labels (material + sorting pictograms by ~2028) and plan a GS1 Digital Link QR for specs/proof.

Phase 2 — Concept & Prototype (Week 3–8)

- Material decision: start fibre-first where barrier is moderate; use DfR-compliant plastics where high barrier is critical. Tie each concept to a named stream (e.g., “paper—standard mill” or “PE film stream”).

- Barrier selection: for fibre, specify PFAS-free dispersion/CNF stacks and plan a repulpability check; for plastics, pre-check EVOH%/adhesive against stream limits.

- Make A/B prototypes: 2–3 variants per SKU (e.g., coated board vs. molded fibre fitment). Keep mono-material and avoid NIR-problematic blacks unless certified detectable.

Phase 3 — Lab Validation (Week 6–10)

- Transit protection: run ISTA 3A (parcel/e-com) or ASTM D4169 (distribution) to prove protection and right-sizing.

- Shelf-life/functional: check OTR/MVTR/grease to minimum viable spec (don’t over-barrier).

- Recyclability:

- Fibre → submit to Papercycle/CPI (states compatible mill types) and document coating repulpability.

- Plastics → map full bill of materials to RecyClass guidelines (caps/labels/inks/colours/EVOH/adhesives).

- Artwork & labels: stage PPWR pictograms and link QR to a public spec evidence page (DfR results, certifications).

Phase 4 — Pilot in 1–2 Markets (Week 10–14)

- Volume: ~5–10% of annual run, mixed channels.

- KPIs: damage rate (pp), consumer disposal understanding (scan rate on QR), EPR fee delta, return-to-stock time.

- Operator feedback: 3PL/retailer handling notes, line speeds, sealing quality, print durability.

- Decision gate: if transit or recyclability flags emerge, adjust barrier stack (fibre) or EVOH/adhesive (plastics) and re-check against DfR.

Phase 5 — Scale & Standardise (Week 14–24)

- Rollout plan: expand to remaining EU markets prioritising those with confirmed collection/sorting for your target stream (e.g., PET bottles vs PET trays differ—don’t over-claim).

- EPR contracting: update PRO registrations, fee coding and product weights; bank the eco-modulation benefits for recyclable designs.

- Supplier playbooks: freeze spec + DfR mapping + recyclability certificate, add incoming QA for barrier mass/ink set/adhesive, and publish artwork rules (colours, no carbon-black unless NIR-detectable).

- Governance: appoint spec owners (engineering + compliance) and run quarterly evidence pack audits so claims remain current (especially compostability per EN 13432 if used).

Your Next Move with Molded Fiber

Switching to molded fiber isn’t a cosmetic choice—it’s a strategic upgrade. You get a premium, tactile unboxing experience, curbside paper-stream recyclability when designed with repulpable, PFAS-free barriers, and a clear compliance path under the EU’s PPWR and EPR. The materials are mature (wood pulp, bagasse, bamboo), tooling is fast, and performance now covers most non-extreme barrier needs.

Operationally, molded fiber helps you right-size packaging, reduce void, and cut damage/returns—often lowering total cost once EPR fees, freight cube, and reverse logistics are included. Most importantly, it gives you evidence-ready claims: name the target stream (paper), map to 4evergreen guidelines, and file a Papercycle/CPI recyclability determination and PFAS-free barrier spec. That’s how you ship a beautiful pack that also stands up to audits.

If you’re aiming to pilot molded fiber in the next quarter, start with 1–3 SKUs where barrier needs are moderate. Build A/B prototypes (dispersion-coated board vs. molded-fiber fitment), validate with ISTA/ASTM transit tests, and publish a short, public QR evidence page (DfR + recyclability + certifications). From there, scaling is straightforward.

Want your next packaging audit to be a non-event?

If you’re serious about defensible sustainability claims, the fastest path is combining design-for-recycling decisions with an evidence pack your legal team can stand behind.

Request a consultation and we’ll help you:

– pick 1–3 SKUs with the best “switch potential”

– map claims to scope + proof

(so marketing language becomes audit-ready)

– explore molded fiber (wet-molded) directions

that fit real recycling streams