Pulp Molding:

The Essential Guide to Molded Fiber Packaging

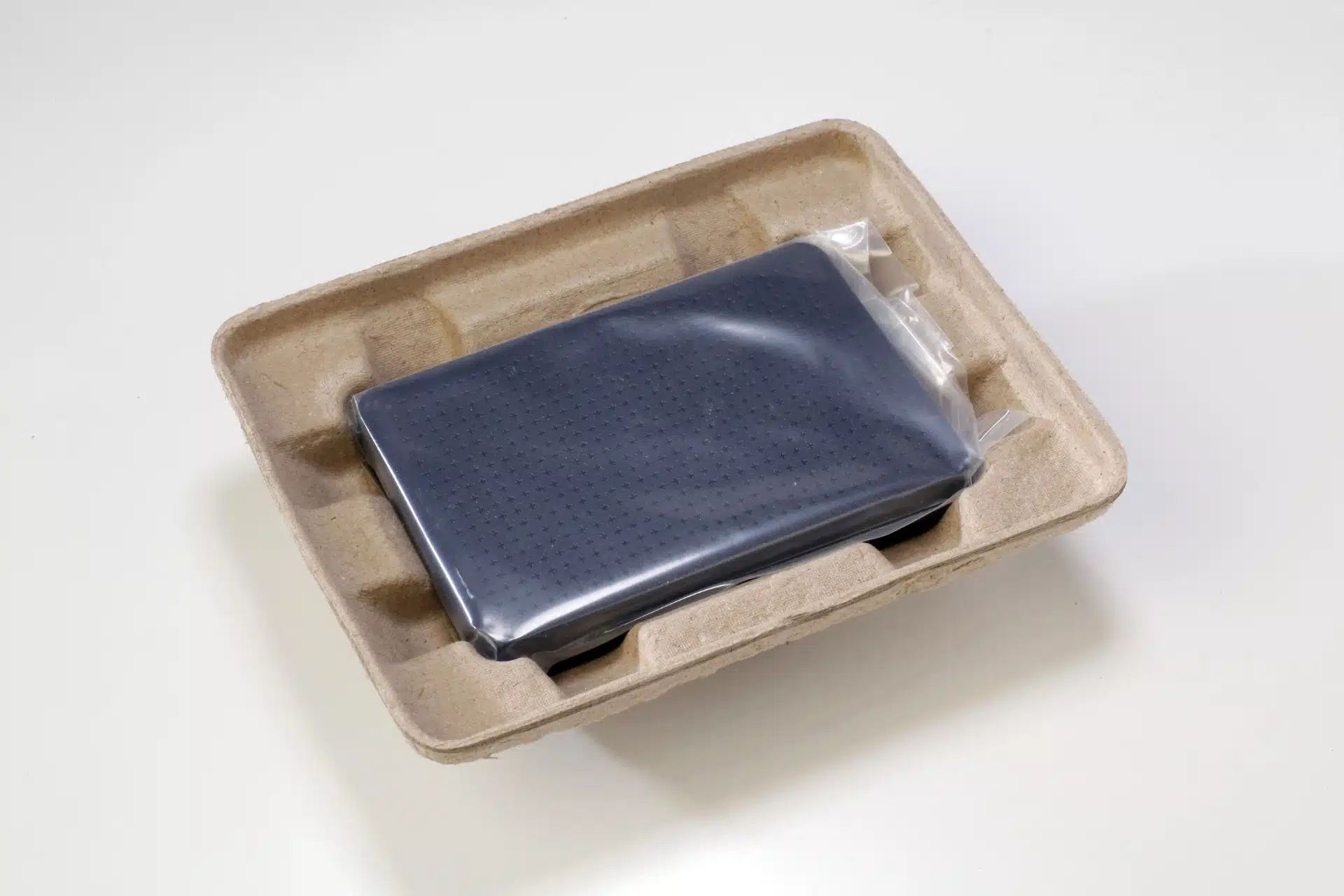

Pulp molding – often referred to as molded fiber or molded pulp products – is a manufacturing technology that turns paper pulp and other natural fibers into precise, three-dimensional packaging parts. Instead of relying on rigid plastic trays and foams, the pulp molding process uses water, vacuum and heat to create molded fiber packaging: inserts, clamshells, tableware and other components that protect and present your products. For many brands in the packaging industry, these fiber-based formats have become a core sustainable packaging and eco-friendly packaging solution, and this essential guide explains how pulp molding works end-to-end for technical and commercial buyers.

Throughout the article, you’ll see how molded fiber compares to plastic in performance and cost, how different raw material mixes (wood pulp, sugarcane bagasse, bamboo pulp, wheat straw and recycled paper) behave in the process, and what the environmental impact looks like when you shift to fiber-based formats. We’ll also cover barrier options and moisture resistance, cost and ROI, timelines for switching, challenges and limitations, plus real use cases. The goal is simple: show you how to use molded fiber technology to reduce environmental impact, cut plastic and de-risk the transition in real portfolios.

On this page:

What is pulp molding and molded fiber packaging?

Pulp molding is a manufacturing process that creates molded fiber parts – trays, inserts and shells formed from pulped fibers instead of plastic. Rather than melting resin, the line starts with a slurry of paper pulp made from recycled material and plant-based fibers such as wood, sugarcane bagasse, bamboo or wheat straw. The mixture is drawn onto a tool with vacuum, then pressed and dried so the fibers lock into a rigid molded product with the required shape and strength. The same technology is used for everything from egg trays and clamshells to fitments that keep products in place during transport.

In short, pulp molding is the technology; molded fiber is the output. In the industry and in organisations such as the International Molded Fiber Association you’ll also see terms like molded pulp or fiber-based trays. Within this family there are several variants – thick-wall parts, transfer-molded trays and fine-edge thermoformed fiber – which all rely on the same basic process but deliver different surface quality, tolerances and cost levels. What they have in common is that they use renewable fibers and are designed as a lower-impact, eco-friendly alternative to traditional plastic formats.

How the pulp molding process works (step-by-step)

The pulp molding process looks like three-dimensional papermaking. It starts with stock preparation: recycled paper, cardboard offcuts or other fiber materials are mixed with water in a pulper to create paper pulp. This slurry is refined, screened and adjusted for viscosity so it runs consistently on high-volume lines.

Once the furnish is ready, forming begins. A metal tool is submerged or sprayed with the slurry and vacuum is applied from the inside, pulling fibers onto the mesh and building up the wall thickness. In transfer molding, the wet “preform” is handed over to a matching mold that defines the visible surface and critical dimensions. In thermoformed fiber, heated tools compress and partially dry the part in-mold, improving edge quality and dimensional stability.

After forming, parts go through drying and finishing. Depending on the design, they may be oven-dried, in-mold dried or run through a combined system, then trimmed, punched and checked inline. This is where you fine-tune tolerances, vent holes, draft angles and de-nesting behaviour for automation. The result is a fiber-based solution tailored to specific protection and handling requirements, produced on equipment that uses recycled materials and natural fibers instead of virgin plastic – a good example of pulp molding products delivering performance at scale.

Materials and barrier systems in molded pulp packaging

Molded fiber starts with the right raw material mix for the technology. Most commercial parts today use recycled paperboard blended with wood pulp, while more and more projects add sugarcane bagasse, wheat straw or bamboo pulp as extra fiber sources. These streams are not the end product themselves – they are feedstock for the molding process, where pulping and forming convert them into rigid, three-dimensional components with the required strength, stiffness and surface. Because these fiber-based structures are often biodegradable or compostable in suitable systems, they fit well into modern sustainable packaging strategies.

When designed correctly, paper pulp packaging can be recycled in existing paper streams or, in some cases, industrially composted, while still delivering the barrier and performance levels modern brands require.

Since the base fibers absorb water and grease, barrier design is critical. For dry goods, industrial trays and many outer packs, uncoated fiber parts work well and remain easy to recycle – and in some systems even compost. For food, tableware, cosmetics or chilled applications, producers add internal sizing or thin bio-based and polymer coatings during production to achieve the required level of moisture and grease resistance.

The most advanced solutions use selective or partial coatings – only where contact is expected – so most of the structure remains repulpable while still meeting performance and shelf-life targets.

Molded fiber packaging vs plastic:

performance, cost, and disposal

From a protection point of view, molded fiber is used in very similar ways to plastic and foam inserts. Electronics, small appliances and other fragile items routinely ship in fiber trays that hold products in place, manage clearances and survive drop tests. When the geometry is well engineered, these parts can match plastic on shock absorption, stack strength and behaviour in transport and storage. That’s why you now see molded fiber clamshells and trays replacing foamed plastics in use cases ranging from chargers and routers to cosmetics gift sets.

For many brands, pulp molding packaging has already replaced plastic clamshells and thermoformed trays in retail and e-commerce channels while maintaining the required level of product protection.

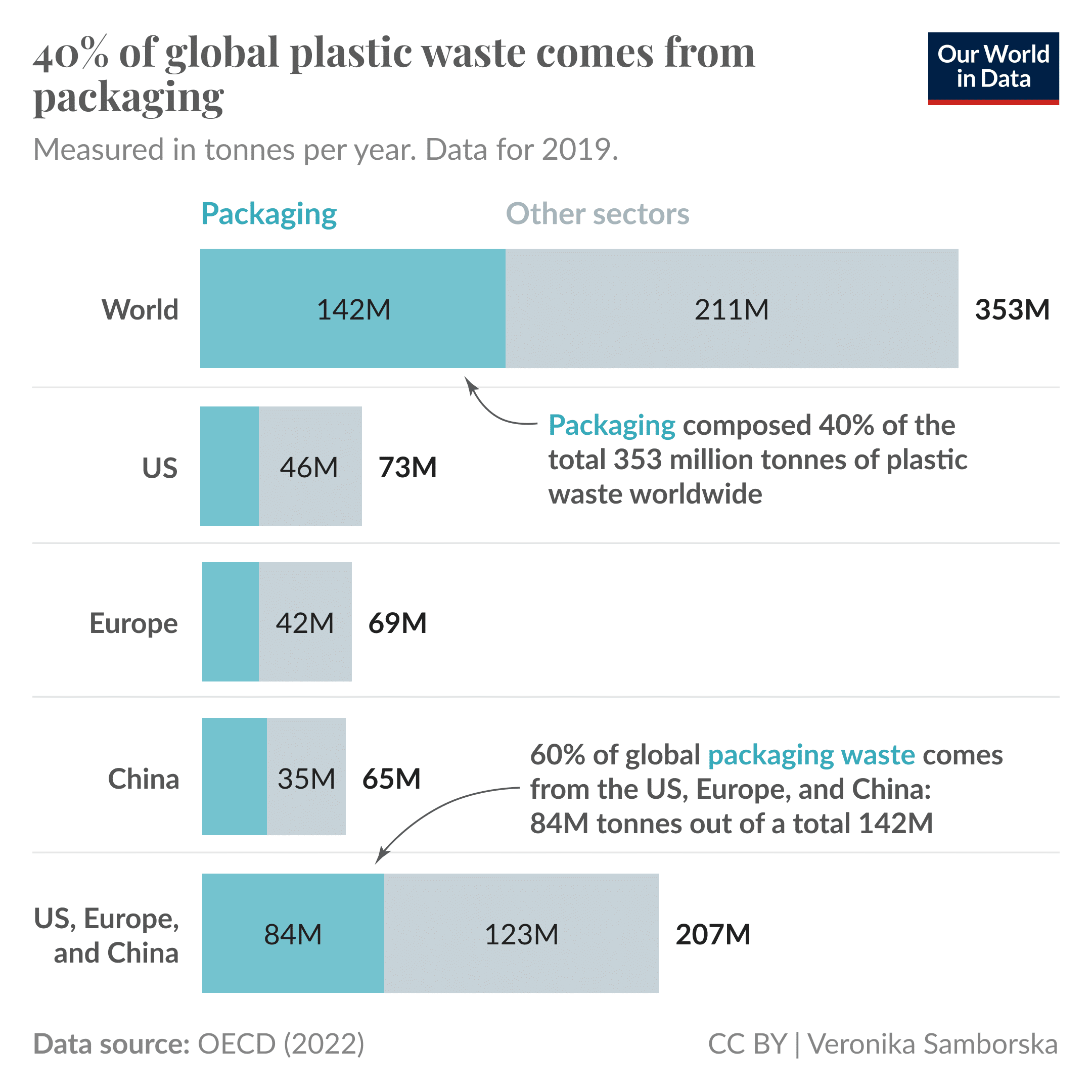

The biggest contrast appears at end of life. Around 40% of the world’s plastic waste comes from packaging, according to analysis by Our World in Data, based on global waste and material-flow data (Source: Our World in Data – “Packaging is the source of 40% of the planet’s plastic waste”,

By comparison, paper and cardboard – including many fiber-based formats – have the highest recycling rates of any packaging material in Europe, at around 83% in 2022, according to Eurostat figures summarised by Two Sides (Source: Two Sides – “Paper Packaging Is Recycled More Than Any Other Material”.

This doesn’t mean every tray is recovered, but it explains why brands see pulp molding as a way to hit waste-reduction and climate targets.

On cost and total cost of ownership (TCO) the picture is more nuanced. For simple trays and egg packs, molded fiber is often less expensive or highly competitive, especially in large runs. For complex, highly branded designs, unit price can be similar to or slightly higher than plastic, but you may gain on secondary material savings, damage-rate improvements, better cube efficiency and EPR fees. Supplier LCAs and case studies – for example from Lian Industrial and OtaraPack – suggest that molded pulp formats can use 40–50% less energy and water and emit substantially less CO₂ per kilogram than equivalent plastic packs.

Together, these factors are why molded fiber is now treated as a mainstream sustainable packaging solution, not a niche experiment.

Sustainability, certifications, and CO₂ impact of pulp molding

From a sustainability angle, the value of pulp molding lies in using molded fiber technology to transform recycled and bio-based fibers into functional parts. Instead of producing new plastic, you run paper pulp, wood-based fibers, sugarcane bagasse, wheat straw or bamboo pulp through the molding process and turn them into trays, clamshells or tableware that can be recycled or composted depending on the design and local systems. Done well, this helps reduce environmental impact and regulatory risk and positions molded fiber as a credible low-carbon choice in many categories.

Because molded fiber sits inside the broader paper-recycling ecosystem, it benefits from the relatively high collection and recycling rates of paper and board. Eurostat data, summarised by industry groups like Two Sides and Pro Carton, show that paper and cardboard packaging reached around 83% recycling in Europe in 2022 – the highest of any packaging material (Sources: Two Sides – “Paper Packaging Is Recycled More Than Any Other Material”)

At the same time, LCAs and supplier studies consistently show that pulp-molded formats can use less energy and emit fewer greenhouse gases than equivalent plastic items – for example, reports up to 40% lower energy use and 50% less water for molded pulp compared with plastic packaging production.

When you combine these fundamentals with credible certifications – such as FSC® or PEFC for responsible fiber sourcing and EN 13432 for industrial compostability – molded fiber becomes a robust way to improve the CO₂ profile of your packaging portfolio.

Cost, ROI, and timelines for switching to pulp molding

From a cost perspective, molded fiber is competitive for many simple and mid-complexity designs, particularly when parts run in high volumes. Using recycled fibers instead of resin reduces exposure to volatile polymer prices and future plastic-related taxes, and helps demonstrate progress against internal sustainability KPIs. Beyond unit price, a well-designed fiber tray can also support lower damage rates and better pallet utilisation.

When you look at total cost of ownership, several extra levers appear:

- Materials and fees: lower dependence on fossil-based resins and plastic-specific charges.

- Transport and storage: lighter, better-stacking parts that improve cube and reduce handling complexity.

- Damage and returns: inserts shaped exactly to the product often cut breakage and associated costs.

- Compliance and risk: fiber-based solutions are easier to defend under tightening EPR and plastic rules.

The main up-front spend is tooling and project setup. For most custom parts you’ll go through design, tooling, off-tool samples and line trials before scaling. Once tools are approved, the same molding process is used to run high-volume orders for electronics, food and industrial goods. For brands and packaging manufacturers, that makes pulp molding a realistic way to balance cost, performance and long-term sustainability in a future-proof pack architecture.

Ready to test molded fiber on a real line?

We’ll review your current pack, risk points and line constraints, then propose a molded fiber concept you can actually trial.

Challenges, limitations, and innovations in molded fiber packaging

Even though molded fiber provides a strong alternative to conventional materials, it isn’t a cure-all. Because the process pulls fibers onto a tool with vacuum and then dries them, there are limits on very thin walls, sharp radii and tiny details. To keep de-nesting smooth and OEE high, you usually need generous draft angles, venting and minimum feature sizes. For high-precision fits in electronics or healthcare kits that can be a constraint: the design needs to respect the process window rather than copying every millimetre of an injection-moulded part.

Moisture is the other big challenge. Base fibers are absorbent, so real water resistance depends on barrier choices. Uncoated fiber works well for dry trays, industrial uses and many outer packs, but it isn’t fully waterproof. For hot or wet food, chilled applications or oily products, you’ll need internal sizing or a coating system, which can complicate recycling or composting. Each project has to strike a balance between barrier performance and environmental credentials.

The upside is that innovation is moving fast. Fine-edge thermoformed fiber and new dry-molding approaches deliver sharper edges, smoother surfaces and shorter cycle times, making fiber formats suitable for premium cosmetics and consumer electronics. At the same time, advanced bio-based barriers improve moisture performance while keeping end-of-life options as circular as possible. In practice, molded fiber now offers a growing toolbox of renewable, eco-friendly packaging options – you just need to be clear where it’s the best fit, and where a hybrid or different material still makes more sense.

Case studies and real-world results

In electronics and industrial goods, brands use fiber trays and shells to replace complex foam and rigid plastics. Dyson, for example, reported cutting transport damage by about 30% and reducing supply-chain emissions by 19% after moving certain products to compostable molded pulp packaging, according to analysis by LoveTree Pak

(Source: LoveTree Pak – “Why Are Apple & Dyson Switching to Molded Pulp Packaging?

That’s a clear example of how well-engineered fiber trays can protect fragile devices as effectively as conventional inserts, with a lower footprint.

For trays and inserts in high-volume programmes, some suppliers report similar results. BonitoPak cites customers who switched to molded fiber trays and reduced shipping damage by 45%, cut packaging costs by 35% and decreased storage space needs by 40%, thanks to better stacking and line efficiency.

In food service and tableware, molded items made from recycled and agro-based fibers are increasingly replacing single-use plastics in cups, lids, plates and takeaway formats. Supplier overviews and LCAs show that molded pulp tableware can use substantially less energy and water and deliver much lower CO₂ emissions per kilogram than comparable plastic items, while being biodegradable and compostable in the right systems.

Together, these examples show how molded fiber turns waste streams into functional parts that deliver on performance, cost and sustainability in real-world use.

Conclusion: is pulp molding right for your packaging?

Pulp molding is first and foremost a molded fiber technology – a way of turning recycled and plant-based fibers into protective, three-dimensional parts instead of relying on plastic and foam. By running your designs through this process, you can create trays, inserts and shells tailored to your products and lines, from e-commerce and industrial shipping to cosmetics, food and healthcare. The result is an eco-friendly packaging solution that supports your sustainability goals while still performing in transit and on shelf.

If you want to explore where molded fiber could replace plastic in your portfolio, Intrecore can help you de-risk the technology side. We work with technical and commercial teams and with every relevant molded pulp packaging manufacturer in the ecosystem to define the right fiber mixes, design parts that run on real packing lines, and validate performance through trials and testing. Get in touch with the Intrecore team to map out how molded fiber and the pulp molding process could become a scalable, low-impact platform in your next generation of packs.

Ready to see where molded fiber really fits in your portfolio?

If you want to understand the technical risks, cost implications and sustainability impact of switching from plastic to molded fiber, the Intrecore team can help.

We’ll review your current packs, map realistic substitution options and outline a clear trial plan you can take back to your stakeholders.