Switching to eco-friendly packaging:

how to move from plastic to fiber without disrupting your lines

Sustainable packaging has become a board-level topic, but actually switching to eco packaging across a full portfolio is where most teams get stuck. If you own line efficiency, damage rates or EPR fees, you don’t just want slogans about sustainable packaging and eco-friendly packaging – you want a guide to sustainable packaging that shows how to move from plastic to fiber without breaking your operations.

At Intrecore, that roadmap usually means shifting from plastic formats into wet molded fiber trays and inserts. This fiber-based packaging material can be designed to be recyclable, compostable or biodegradable, while still protecting electronics, beauty products and food and beverage items. The goal of this article is simple: give packaging engineers, retail category managers and SMEs a step-by-step way to make the transition towards more sustainable fiber formats, with clear trade-offs, realistic risks and a practical path to implementation.

Why switching to eco-friendly packaging needs a portfolio plan,

not a one-off swap

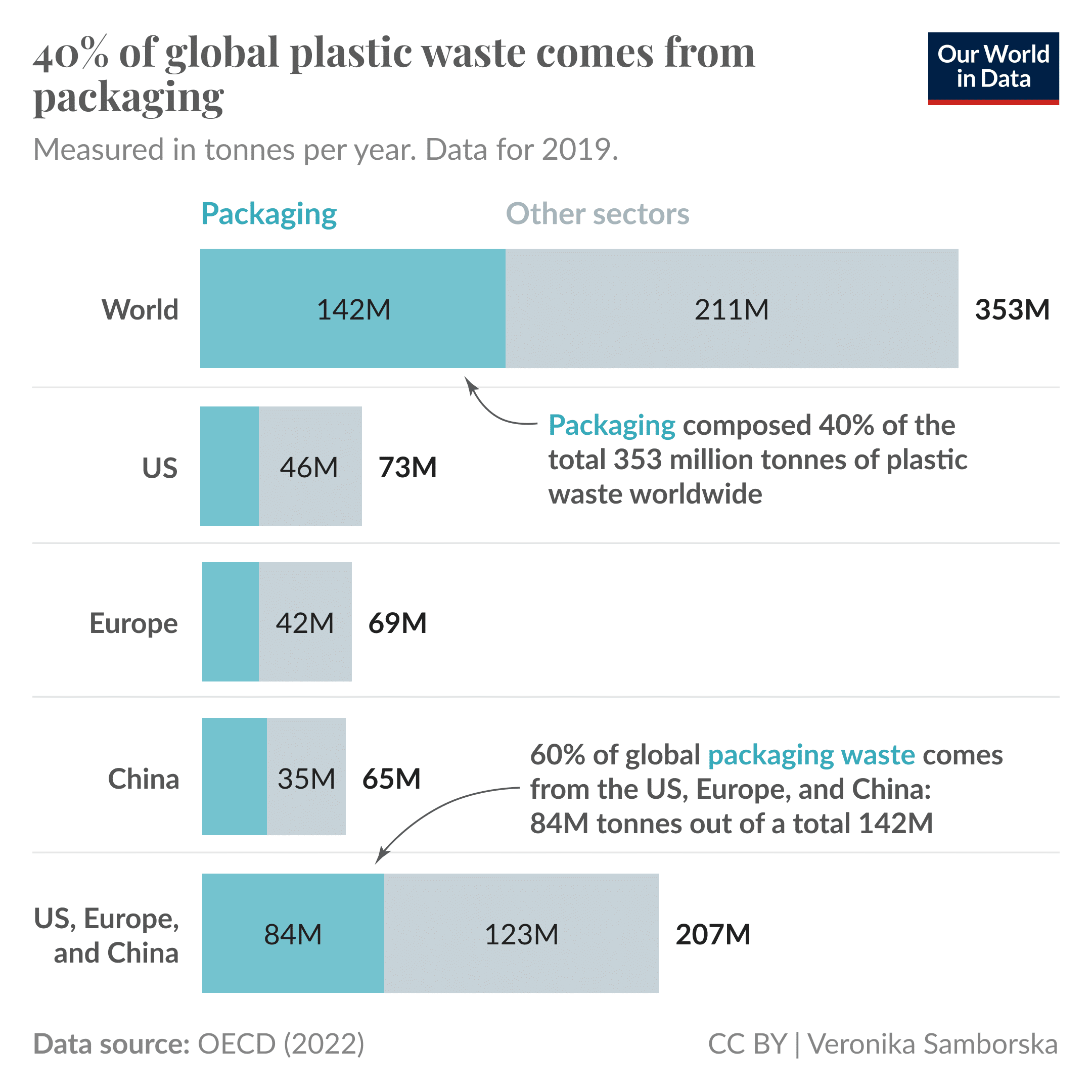

If you treat switching to eco-friendly packaging as a one-off swap on a single hero SKU, you barely dent the problem. Recent analysis based on the OECD’s Global Plastics Outlook shows that around 37–45% of plastic waste in major regions like the US, Europe and China comes from packaging – roughly 40% of the total. In the EU, 2023 data shows 79.7 million tonnes of packaging waste, or 177.8 kg per person, including a large share of plastic packaging waste. Packaging is one of the fastest levers you have to cut plastic, reduce packaging waste and minimise environmental impact.

At the same time, the molded fiber packaging market is growing quickly. One market report estimates it at around USD 7–8 billion in 2022, projected to reach over USD 12 billion by 2030, driven by demand for sustainable packaging materials like molded fiber that are compostable, biodegradable and often made from recycled materials. That tells you two things: regulators are pushing harder, and your competitors are already exploring fiber-based solutions. To stay ahead, you need a portfolio-level plan that links packaging choices to sustainability goals, emissions and costs – not just a nice story on one eco mailer.

Sources:

https://ourworldindata.org/data-insights/packaging-is-the-source-of-40-of-the-planets-plastic-waste

https://www.sciencedirect.com/science/article/pii/S2352550924002823

https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Packaging_waste_statistics

https://ec.europa.eu/eurostat/web/products-eurostat-news/w/ddn-20251022-1

https://www.fortunebusinessinsights.com/molded-fiber-packaging-market-104894

Step 1 – Map your current packaging portfolio and pain points

Start with a simple but ruthless audit of your current packaging. For each SKU, capture:

What’s being packed (including any specific product sensitivity)

- Sales channels (retail, e-commerce mailer, 3PL)

- Materials in use – plastic packaging, cartons, foams, materials like PLA or coated boards

- Issues: damage, returns, over-packing, line slowdowns, complaints

This gives you a baseline on packaging waste, weight, and where reducing packaging volume or complexity could lower shipping costs and emissions. You’ll also see where packaging doesn’t really add value – for example, a piece of packaging that exists “just in case” but rarely prevents damage.

Then capture pain points from operations and the supply chain: SKUs that are awkward to pack, inserts that jam, or formats that create rework in co-packing. Wet molded fiber can often simplify those areas because it can be molded precisely around each specific product using organic materials and recycled fibers. That combination of better fit and lighter packaging is where switching to fiber can cut damage and improve sustainability at the same time.

Step 2 – Prioritise the right SKUs to switch first

The big strategic question is “Can we replace plastic everywhere?” The honest answer is no – but you can usually transition to more sustainable formats on a meaningful part of your portfolio.

Prioritise SKUs where:

- Products are robust or already have strong primary product packaging

- Geometry is repeatable (device families, standard beauty kits, simple food formats)

- A fiber tray could drop into existing packaging lines with minimal tooling changes

Think of a mid-size cosmetics brand shipping glass serum bottles. In one public case study, a similar brand replaced plastic clamshells with molded pulp trays made from sugarcane fibers and cut its packaging waste by about 50%, while increasing sales of “green” product lines by roughly 20%. That’s the kind of opportunity you’re looking for: high-volume SKUs where switching to molded fiber drives both environmental impact reduction and commercial upside.

For fragile or chilled products, you can still move towards more sustainable options, but test more carefully. Some packs still need barrier films or hybrid designs to avoid food waste and protect food safety. The goal is not perfection overnight; it’s a realistic roadmap that moves the portfolio step by step towards eco-friendly packaging solutions.

Step 3 – Compare eco materials and suppliers

(including trade-offs)

Once you know which SKUs to target, you can compare sustainable packaging alternatives. For each option, look at:

- Performance (cushioning, stacking, moisture, thermal behaviour)

- End-of-life (recyclable, compostable, biodegradable, likely landfill)

- Cost, lead time and resilience of the supplier base

Wet molded fiber made from recycled materials or agricultural fibers is attractive because it can be designed as biodegradable packaging, compostable or recyclable, and fits into existing paper streams in many markets. Studies on molded fiber highlight that these materials reduce plastic dependence, lower packaging waste and often improve carbon footprint compared with traditional plastics.

For credible, audit-proof decisions, don’t just trust marketing slides. Ask each supplier for clear data on emissions, recycled content, certification for compostable packaging or recyclable claims, and the source of fibers. In some markets, composting facilities are still limited, so recyclable fiber might be a better sustainable option than compostable materials that end up in landfill. The key is to choose eco-friendly packaging alternatives that your infrastructure can actually handle.

Sources:

https://www.sciencedirect.com/science/article/pii/S2369969821000803

Step 5 – Check compliance, recyclability and carbon / ESG reporting

Before you scale, make sure your new solutions really support your sustainability initiatives and compliance obligations.

That means checking:

- Fit with local and EU packaging regulations (such as PPWR)

- Whether the format is realistically recyclable or compostable in core markets

- How it affects emissions and carbon footprint across the supply chain

EU data on packaging waste shows that even as recycling improves, overall volumes remain high, and plastic packaging waste per person is still a major challenge. Against that backdrop, molded fiber solutions to help replace plastic can be a credible way to minimise environmental impact. Use LCAs, supplier data and recognised frameworks (for example, from organisations similar to the Sustainable Packaging Coalition) so that your ESG team can confidently report emission reductions and progress toward sustainability goals.

Source:

https://foodpackagingforum.org/news/packaging-waste-data-from-the-eu-and-california

Step 6 – Run a controlled pilot and fix issues early

With designs and data in place, run a pilot before rolling out across the whole portfolio.

Choose:

- A limited number of SKUs

- One or two plants or 3PL sites

- A clear time window and KPIs

Track line speed, scrap, damage rates, returns and feedback from operators and customers. This is where you catch practical issues – a tray that sticks in automation, a mailer that scuffs, or a fiber geometry that needs a tweak. Adjusting wall thickness, ribs or nesting during the pilot is much cheaper than re-tooling after a full launch.

Step 7 – Scale the transition and monitor over time

Once the pilot is solid, scale out by category, market or region.

As you do, monitor:

- Cost per packed unit (including any changes to shipping costs)

- EPR and plastic-related fees

- Damage, return and complaint rates

Over time, this monitoring shows where molded fiber formats consistently perform better than traditional plastics, and where you might still need a hybrid. It also gives you hard numbers to show that adopting sustainable packaging isn’t just a green claim – it’s improving pack performance and the bottom line.

Step 8 – Tools and resources for packaging teams

To keep momentum, standardise what you’ve learned:

- A simple scorecard to compare fiber, plastics and other sustainable options

- A short test checklist (transit, food safety, recyclability / compost)

- A shared library of approved biodegradable and compostable materials and pack formats

These tools help companies avoid reinventing the wheel every time they explore eco-friendly packaging options and make it easier for new projects to follow the same, proven path.

Wrapping up – and how Intrecore can help

Sustainable packaging and eco-friendly packaging are no longer niche projects; they’re part of how brands compete. The data is clear: packaging is responsible for a large share of plastic waste, while molded fiber and other sustainable packaging solutions are growing fast as brands look for ways to reduce their footprint without compromising performance.

Intrecore is committed to sustainable, fiber-based formats that work in real factories, not just in decks. Whether you’re exploring biodegradable materials, compostable packaging for beauty kits, or recyclable molded fiber trays for electronics, we can help you choose eco-friendly packaging alternatives, design and test them, and scale without disrupting your lines.

If you’re planning a project on switching to eco packaging and want a partner who understands both molded fiber and operations reality, reach out to the Intrecore team – we’re happy to look at your portfolio and help you design the next generation of truly sustainable packaging.

Ready to see if molded fiber works on your lines?

If you’re responsible for line efficiency, damage rates or packaging development, let’s look at your current portfolio together and map where fiber can replace plastic without slowing you down.

Quick answers about switching to eco packaging

Is eco-friendly packaging suitable for fragile or food items?

Yes, if it’s engineered and tested properly. Wet molded fiber trays can protect electronics, glass and food and beverage SKUs, as long as you validate cushioning, stacking and food safety in real tests.

Can this be recycled or composted—or does it end up in a landfill anyway?

It depends on the design and the local system.

Many molded fiber formats are recyclable in paper streams; certified compostable products need access to composting facilities. Where infrastructure is weak, some packs will still go to landfill, so design with real end-of-life routes in mind.

Can we replace plastic completely?

In most portfolios, not yet. But you can significantly reduce plastic use and packaging waste by swapping the right SKUs first and using molded fiber where it’s a robust alternative to conventional foam and rigid plastic.